How Print and Apply Labeling Can Increase Production

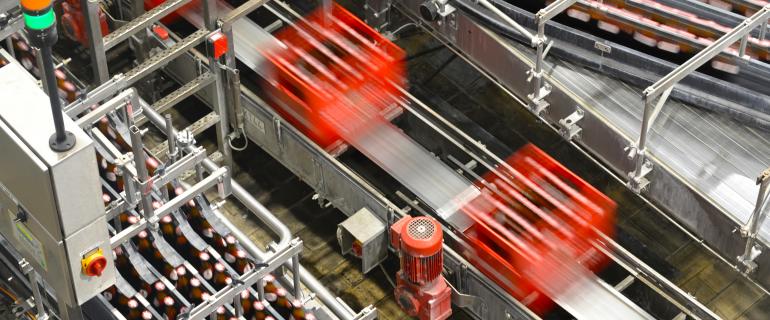

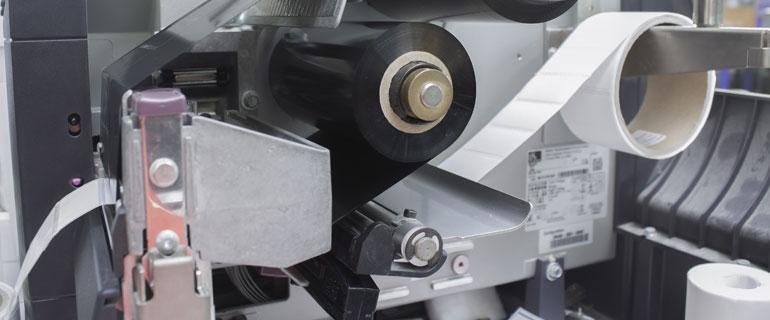

Adding a print and apply labeling system to your production line can increase throughput, reduce costs, and provide efficiencies for nearly every operation out there. While many production equipment considerations have pros and cons, print and apply systems beat out traditional pre-printed label systems by nearly every possible metric.

Because of the advantages print and apply label machines offer, every packaging and manufacturing operation should take the time to weigh their options for migrating to the more modern system. When they do, they’ll obtain the following advantages, all of which lower costs and complexity while raising throughput.